If you have been in manufacturing for more than 5 minutes you are familiar with the Japanese concept of 5S (Sort, Set, Shine, Standardize, Sustain). This is a universal concept, but many people have placed this methodology in a very limited application. When I was coming up in organizations, we described this methodology as something that was done to tidy up an area, or make sure all your tools were back on the shadow boards after maintenance; however, this methodology is used to tidy up LIFE. We can see the use of 5S in APQP if we just expand our scope from the limited view of what the tool SHOULD BE, to what the tool COULD BE. APQP at its core is simply 5S applied over to program management …however you have to do your part – you will ultimately be responsible for standardization and sustainability (after all you cannot expect a tool to do everything for you). Let’s explore each “S” below.

Sort

When we begin APQP we must sort things, and so the first question that is asked is “what are common phases that ALL programs go through, irrespective of it they are aerospace, healthcare, education or anything else. Collectively in APQP we agree that there are 5 phases.

These are the phases we generally subscribe to in APQP… but we now need order, we need to SET them in some form of sequence.

Set

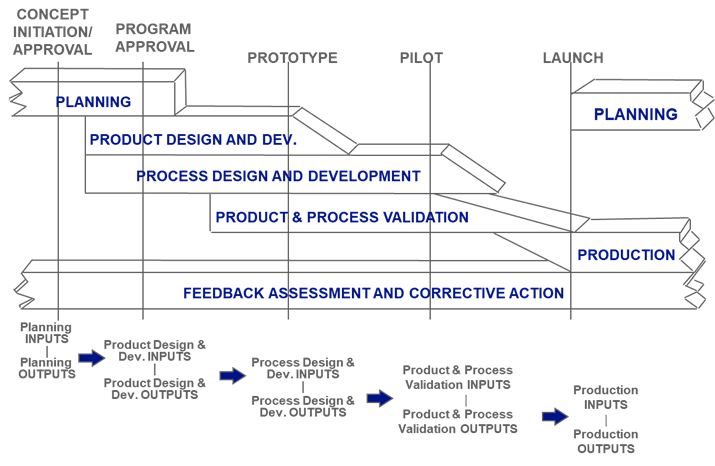

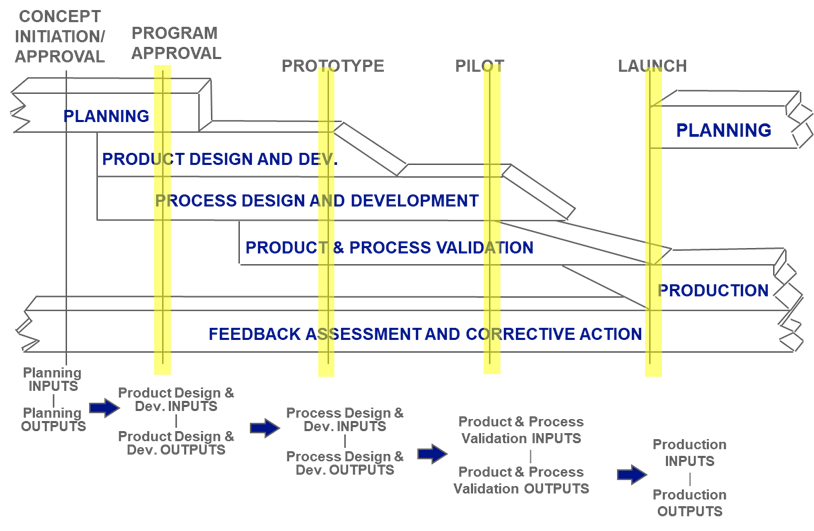

The 5 phases of APQP are SET in order utilizing the below diagram. This diagram shows “WHAT TOUCHES WHAT”. Notice a few things about this diagram.

Now that we have the phases and they have order, we should look at how we EVALUATE the phase to determine its level of acceptability, or in 5S terms … how we SHINE it.

Shine

In analogy we need to pump the brakes occasionally on the program and decide if it is delivering on what it needs to in order to arrive where we intend to go. So, we put in gateways, or checkpoints, or any other term you want to use to denote a point where you stop and REVIEW. In APQP each phase is marked with a checkpoint where the tasks are evaluated and the fitness for the process to move to the next phase is evaluated.

Standardization and Sustainability

The final 2 S’s are up to you, as APQP does not know your business, and it is applicable to organizations of various shapes and sizes. How you will implement APQP will depend on many factors like your company size, your commodity, your industry…the list goes on and on. Regarding sustainability, this will come down to things like your QMS and corporate culture, and that is a topic for another blog.

So, in summary, all APQP is the program management version of 5S, and if we step back, we can see that it is not terribly complicated when applied to the 5S framework.

Subscribe to our newsletter.