Advanced Product Quality Planning (APQP) is a structured method to define and establish the necessary steps required to meet all Customer Specific Requirements (CSRs) in any new launch or product planning process. The APQP process serves as a guide in the product development process, and a standard way to share results between organizations and their customers.*

As a supplier, your customer may require that you implement APQP to implement and maintain their Customer Specific Requirements either through a contractual agreement or other means of communication. If there is not a direct requirement from the customer, suppliers may choose to use the AIAG APQP guideline as best practice within the automotive industry.

In the early 1980’s, Ford published the first handbook to formally address APQP guidelines for suppliers, with Chrysler and GM following suit and developing their own standards for the method. Years later the three OEMs recognized the need for a single APQP guideline and in 1994 released the AIAG APQP Manual with intention of ensuring all organizations within the automotive supply chain will produce a quality plan to support in the development of a product or service that will satisfy the customer and their requirements.

Today, this practice is used across industries and has been developed as the preferred method to facilitate communication between the supply chain and organization or customer.

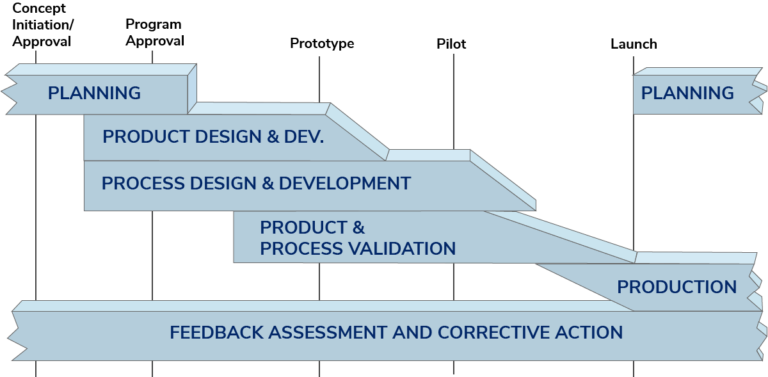

There are 5 phases within the APQP process, each phase happening simultaneously with at least one other while giving output in each phase for input for the next one (see figure 1):

Phase 1 – Plan and Define Program

Phase 2 – Product Design and Development Verification

Phase 3 – Process Design and Development Verification

Phase 4 – Product and Process Validation

Phase 5 – Feedback Assessment and Corrective Action

Plexus International designs, develops, and delivers internationally accredited, industry-recognized training programs for the global manufacturing supply chain with one critical goal: real performance improvement. For more information on APQP or to learn more browse our related trainings.

Sources:

In this Live-Virtual Workshop you will learn the skills needed to implement the APQP process, develop control plans and complete the production part approval process smoothly, efficiently and effectively within your company.

Learn to implement AS9145: Advanced Product Quality Planning (APQP) as part of the New Product Development process, as well as the Production Part Approval Process (PPAP) for Aerospace organizations.

Explore training, consulting, and more for the AIAG Core Tools, including APQP & PPAP, AIAG & VDA FMEA, MSA & SPC and AS9145 for Aerospace organizations.