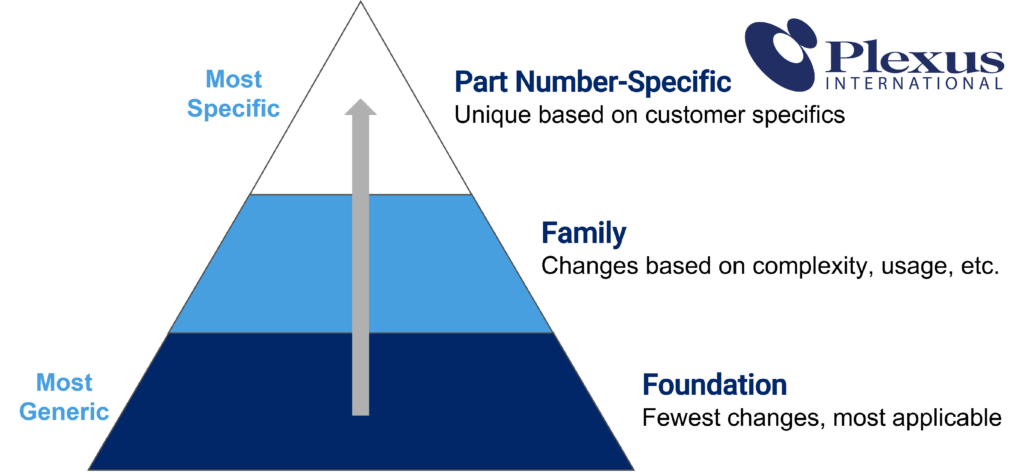

You’ve been asked to do an FMEA for a project but you’re saying it takes too long, we’ll show you how to alleviate that pain point using the AIAG & VDA Foundation and Family FMEA.

The new AIAG & VDA FMEA actually lessens the development time. How? Through using Foundation & Family FMEAs.

What’s the difference in Foundation & Family FMEAs?

Let’s say you’re doing a Process FMEA, and there were things in your Process like cutting or boring a hole that are common to every time you bore a hole. So the same failure modes exist. As an example: holes have diameter, could you be over or under diameter? Sure. Because you are running off the same style of machine, do you have common causes? Such as the bit wearing prematurely, the speed not being correct, the work piece coming loose – absolutely.

You could create a Foundation FMEA around that boring operation that would encompass all of your failure modes as a place to start.

What about Family FMEAs?

Lets say now that you cut metal and plastic materials. There are failures associated with plastic such as as shrinkage caused by heat that you may have in plastic but not in metal. So there may be some unique failure modes to your plastic parts versus metal parts. That would be an example of a Family.

The reason this cuts down on development time is because you no longer have to start from a blank slate. You bring out the Foundation or the applicable Family and you start there and deal in Deltas.

How does this work with DFMEAs?

There are common design elements in what you do, as an example, let’s say you fasten two pieces together. That fastener in your application if you were attaching a body panel to a frame, is going to be the same whether you’re doing Frame A or Frame B – its functionality is to attach. So you don’t have to start all the way back at square one every time you do an FMEA.

1. Bring out the baselines

2. Look at the baselines, and

3. Deal in Deltas

It’s up to each organization how they organize the FMEAs.

Take your existing Process or Product catalog and figure out how you would like to index it from the Foundation and Family side. If you do this, it will cut down your development time substantially because you won’t be reinventing the wheel every time you get a new product.

To learn more about FMEA visit our Blog or browse the New Live Virtual FMEA Bootcamp 2.0 Series, featuring Foundation & Family FMEAs, Auditing the FMEA, and Managing FMEA Development.