As we look at the current state of the auditing world, what we see over and over again are auditing systems that fail to achieve effective quality management system improvement, and furthermore a return on investment. This is often attributed to poor audit planning, but “poor planning” alone does not address the issue at its core. Taking a closer look, we see that even when audit planning has in fact taken place, it was not conducted with the right focus in mind. What we’re talking about is really a matter of audit type hierarchy, where emphasis is placed on the wrong audit type. In other words, audit teams are focusing solely on planning and scrutinizing a system, or process, without regard for the physical product. Today we’ll challenge you to think differently about how you improve an overall quality management system by taking a product-first audit approach.

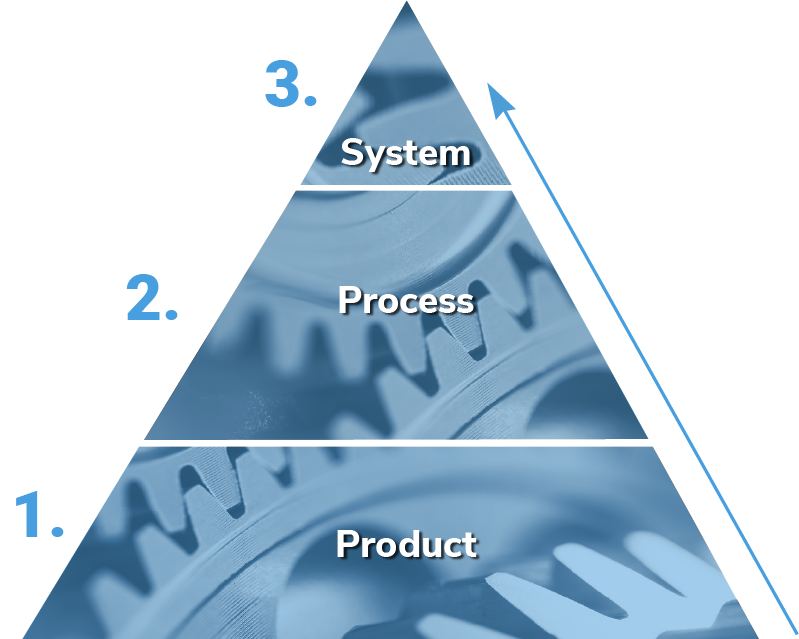

When it comes to auditing IATF 16949 there are three distinct types of audits:

Product Audit

Product audits often receive the least amount of focus of all three audit types. This is because a product audit is seen by many as a form of mere inspection or simple measurement of a product’s characteristic. While this type of audit may seem simple to conduct, it is an audit area that should not be undervalued as it provides critical input used in defining processes and systems.

Process Audit

A system is comprised of various processes. The process audit is commonly perceived as an “engineering” style audit due to its highly technical nature. When conducting this type of audit, one would take the Process Failure Mode Effects Analysis (PFMEA) and the control plan out to the shop floor and walk through the process. This type of audit is extremely important, but should first take into account the process inputs.

System Audit

The system audit is often regarded as the most “prestigious”, or important. It is thought of as the closest thing to an audit of an organization’s “business management.” For this reason many organizations tend to put nearly all focus on planning and auditing the overall system, and forget to improve upon said system as it relates to its processes and the physical product.

The Product-First Approach to Auditing

If you’ve tried time and time again to improve your quality management system with less than desirable results, you may be thinking of the audit hierarchy incorrectly. Spending too much time planning and critiquing the overall system without regard to the specifics of the product leads to ineffective auditing and improvement, followed by unsatisfactory ROI. Why spend the time and effort improving a system without first identify tangible issues within the physical product? The best way to refrain from making this mistake is to continually ask yourself the following question:

“Does my customer directly experience

the PRODUCT, the PROCESS or the SYSTEM?”

Notice the emphasis on the word “directly.” If your answer is that they directly experience the product, then you are correct. In Six Sigma there is a simple equation used to explain the relationship between variables: Y=f(x)

In this equation, Y (an output) is a function of x (an input)

You can never change Y, you simply monitor it.

You can control x, this variable can be manipulated.

Using the above concept from Six Sigma, we can assume that when we implement changes to systems or processes, the product (Y) is an output and a function of the process (x) and system (x). In other words, you can manipulate your system (x) or processes (x), and monitor how these changes affect the product. However, when we think about this concept in the context of auditing, it is a best practice to define your process and system audits in a reverse engineering fashion. Using the product-first approach to auditing, the quality issues found during the product audit become inputs into the process and system audits.

In highlighting the importance of audit planning with emphasis on the product, we can see how the product-first approach is the only way to truly improve the overall system. To change the system or its processes without considering how it will affect the product, would at best be wasteful and, even worse, reckless potential causing harm to the product experience.

Regardless of the industry you operate in, whether you provide products or services, or the size of your organization, it's critical to establish, and continually improve, a quality management system (QMS) that aligns with your business strategy.

This course will assist you in the execution of Process FMEAs using the new AIAG & VDA FMEA Handbook.

This course will assist you in transitioning from the AIAG FMEA 4th Edition to the AIAG & VDA FMEA Handbook.